Applications

Solving the Most Demanding Applications in the Power Generation Industry

Today, now more than ever, the strain on a Power Generation plant and its team can feel enormous at times. Set aside the obvious danger of the job, let’s look at the operational pressures. Most likely, you are dealing with aging equipment, budget restraints, operational efficiency requirements, new regulations, and limited maintenance downtime. Add an unexpected outage due to a malfunctioning machinery to the mix, and your blood pressure has skyrocketed.

What the average energy consumer doesn’t realize is that it takes a vast amount of work needed to plan, execute, and maintain a power generation plant. The electricity that comes through the little outlet on the wall takes a lot of work. All they’re worried about is whether their newest gadget charges properly.

What you need is a partner, someone who understands the ins and outs of the power generation plant. Someone who will listen and help you solve the most pressing of problems at the plant, whether it be a cracking expansion joint that your hoping will hang on until the next scheduled outage or a turbine not working at an high efficient level.

Holz Rubber Understands Your Challenges and is Here to Help.

See, it isn’t about selling more products. It is about being a reliable, customer-centric partner that provides the technical know-how to solve some of your most daunting problems.

Let’s be honest, you probably don’t go home and dream about expansion joints, but we do. We know the ins and outs of how expansion joints work in a power generation plant. Also, we know what it means to you to have the right product in the right location without worrying about unexpected outages. The Holz Rubber team recognizes your budget restraints, and we work with you to provide the highest quality product for each application.

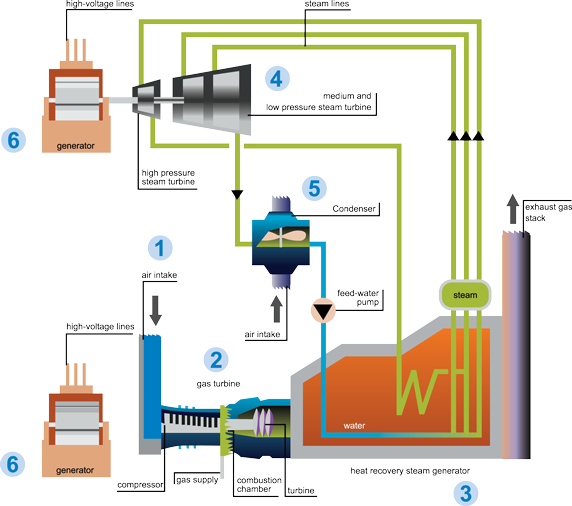

Here is how we can help in various areas of the plant:

Expansion Joint Specifications

- Temperature: 600°F to 750°F

- Media: Clean air from air heater air outlet

- Particulate: Minimal

- Operation: After start up movement is nominal; Severe high pressure operating conditions may be experienced in the primary air ducts of positive pressure boilers

- Pressure: Positive 5″ water column to as high as 80” water column for positive pressure boilers

- Movements: High temperatures will generate moderate compressive movements; Each change in direction in the ductwork will generate a resultant lateral offs

- Insulation/Lagging: Do not lag over the expansion joint; Also, remove lagging from flanges to allow radiant cooling

- Expansion Joint Recommendation: Flue Duct Expansion Joint should be used.

Design Considerations

Type of frame to duct/equipment connection:

- Hot to hot – requires insulated equipment on both sides of the breach opening

- Hot to cold – requires turbine side is externally insulated and the downstream side is internally insulated

- Cold to cold = requires both turbine side and downstream side are externally insulated

Duct configuration – round, square or rectangle

Flow direction – horizontal, vertical or angled

Location with respect to flow directional change

Proximity of the bottom of the expansion joint to the ground. Radiated heat can prematurely damage the outer cover

Turbine manufacturer – model, rated flow, temperature and pressure

Materials of construction for the following components must be compatible with the system operating conditions:

- Frames

- Pillows (when and where used)

- Belts

- Internal flow liners must allow for movement as well as flow protection of the pillow(s)

Expansion Joint Specifications

- Temperature: 1000°F – 1500°F Excursions 1650°F

- Media: Hot exhaust gas from combustion of natural gas or fuel oil. Dry and non-corrosive

- Pressure: Constant positive pressure generally no higher than 20″ Water Gauge; Very turbulent environment

- Operations: Typically online for 12 to 18 months; Power peaking plants may cycle frequently as much as once per day

- Movements: Large compression rating due to the temperature; Lateral movements typically 1″ or lower due to short direct ductwork runs

- Expansion Joint Recommendation: High Temperature Expansion Joint – Holz Series 1000HTF or 12000HTFW should be used

Diverters generally have three (3) ports and all three have expansion joints. These ports are designed as “Cold to Cold” flange arrangements. The bypass portion runs to a silencer and then to a stack. Often times a silencer is incorporated within the stack above the diverter and is supplied as a single package.

Expansion Joint Specifications

- Temperature: 1000°F – 1500°F Excursions 1650°F

- Media: Hot exhaust gas from diverter

- Pressure: Constant positive pressure generally no higher than 20″ Water Gauge

- Operations: Typically online for 12 to 18 months; power peaking plants may cycle frequently as much as once per day

- Movements: Large compression rating due to the temperature

- Expansion Joint Recommendation: Holz Series 1000HTF or 12000HTFW High Temperature Expansion Joint

After the steam is spent in the turbine process, the residual steam leaves the turbine at low pressure and low heat. The purpose of the condenser is to turn low energy steam back into pure water for use in the HRSG. Typical condenser expansion joints are located at the condenser and/or at the recirculating pumps.

Holz recommends its Series 320M Molded Piping Expansion Joint or Series 320 Hand-Built Pressure Piping Expansion Joint should be used.

Related Application Data Sheets

Splicing Instructions Saves Power Station Time & Money

An electrostatic precipitator (ESP) is a large industrial emission-control unit that uses a fabric expansion joint on both the inlet and outlet. An ESP traps and removes dust particles from exhaust gas stream by using an electrostatic charge.

An electrostatic precipitator (ESP) is a large industrial emission-control unit that uses a fabric expansion joint on both the inlet and outlet. An ESP traps and removes dust particles from exhaust gas stream by using an electrostatic charge.

Read more…

Expansion Joints Designed to Prevent Hurricane Damage in Gas Turbine Air Inlet

Gas turbines require a lot of intake air to function properly. As the ambient air is drawn into a Filter House, the air passes through a series of cleaning filters. Next, this large volume of air passes through a Silencer section to quiet the noise before entering into the Turbine Inlet.

Gas turbines require a lot of intake air to function properly. As the ambient air is drawn into a Filter House, the air passes through a series of cleaning filters. Next, this large volume of air passes through a Silencer section to quiet the noise before entering into the Turbine Inlet.

Read more…

Settled Ground Creates Breach Opening at Coal Fired Plant

The customers’ scrubber piping has settled over the years which caused the breach opening to lengthen approximately 1 1/4″ from the installed opening. This amount of additional opening caused the rubber to separate from the reinforcement ply on the outer cover of the expansion joint.

The customers’ scrubber piping has settled over the years which caused the breach opening to lengthen approximately 1 1/4″ from the installed opening. This amount of additional opening caused the rubber to separate from the reinforcement ply on the outer cover of the expansion joint.

Read more…

Technical Knowhow Helps Power Plant Improve Turbine Performance

A Midwest power plant was struggling with a failing expansion joint. Cracks and tears close to the corners were causing a loss of air to the turbine during operation. This loss of air causes turbine efficiency related problems.

A Midwest power plant was struggling with a failing expansion joint. Cracks and tears close to the corners were causing a loss of air to the turbine during operation. This loss of air causes turbine efficiency related problems.

Read more…