Applications

Piping Expansion Joint Construction

How Is It Done?

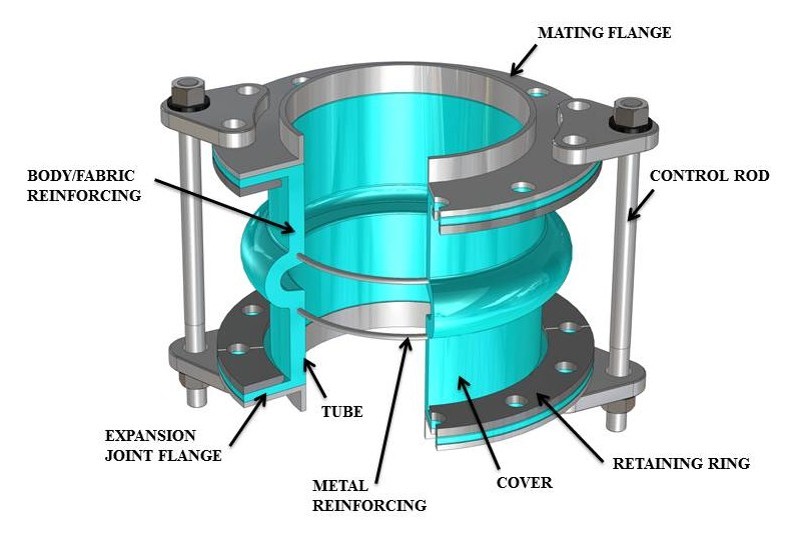

A rubber pipe expansion joint is a flexible connector of two pipes. It provides stress relief in a piping system due to thermal and mechanical vibration or movements. This infographic helps illustrate the piping expansion joint construction. Please scroll to the bottom, where the Holz Rubber team has provided the definitions to help the non-expert better understand the aspects of a pipe expansion joint.

Tube – A protective, leak proof lining made of synthetic or natural rubber. The tubes primary function is to eliminate the possibility of materials being handled penetrating the carcass.

Carcass – The carcass or body of the expansion joint consists of fabric, and when necessary metal.

Cover – The exterior surface of the joint.

Fabric Reinforcement – The carcass fabric reinforcement is the flexibility and supporting member between the tube and cover.

Metal Reinforcement – Wire or solid steel rings imbedded in the carcass, often used for strengthening.

Retaining Ring – Used to compress the expansion joint flange to the mating flange to create a seal. Also called clamp bars or backing bars. Applies to most all expansion joints.

Mating Flange – Used to connect the pipe joint to the pipe in which it is being installed.

Control Rod – Used to limit the axial movements during operation, and prevent the joint from exceeding its movement capabilities. The rods attach the mating flange and expansion joint. Typically used on piping joints, but can be installed on most any joint when required.