High Temperature Expansion Joints

High Temperature Expansion Joints: High Performance Products for Harsh Temperature Environments Offers Long Term Solution

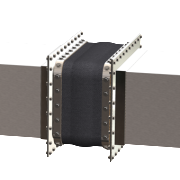

Our commitment to research and development has resulted in the highest performing product offering available for high temperature environments. Engineered for the most severe applications, our high temperature expansion joints are built with a combination of the most advance materials to ensure long life and predictable performance. Holz Rubber offers a full range of complete metal frames, assemblies, and hardware.

Our commitment to research and development has resulted in the highest performing product offering available for high temperature environments. Engineered for the most severe applications, our high temperature expansion joints are built with a combination of the most advance materials to ensure long life and predictable performance. Holz Rubber offers a full range of complete metal frames, assemblies, and hardware.

Advantages of Fabric Expansion Joints:

- Resists Corrosion

- Eliminates Sound & Vibration

- Withstands Temperatures over 2000°F

- Reduces the number of expansion joints because of multi-plane movement

- Shortens face-to-face compared to metal

- Reduces the need for costly toggles, hangers, guides, etc.

- Cuts engineering time significantly

Rubber Chemical-Resistant Expansion Joints (Series 300 LT)

- Designed for use in wet or dry service up to 300°F and 5 psig

- Manufactured from multiple elastomers and offered in either belt or flanged configurations with single or multiple layers of woven fabric or knitted wire

- Typical applications include baghouses, FD fans, wet or dry scrubbers and precipitators

- Designed to operate without a flowliner except in abrasive or high velocity flow scenarios

- Allows external insulation over the flex element if desired

DuPont-Certified Viton® Expansion Joints (Series 400LT)

- Designed for use in wet or dry services up to 400°F and 5psig and to operate without a flowliner except in abrasive or high velocity flow scenarios

- Manufactured using Dupont-certified Viton® and offered in either belt or flanged configurations with reinforced single or multiple layers of woven fabric or knitted wire

- Additional FEP or PTFE gas barrier available to increase chemical resistance where ammonia slip is expected

- Typically used on air heater gas outlets, baghouses, precipitators, induced draft fans, wet or dry scrubbers, and stack breeching ducts

- Can experience excursion temperatures up to 750°F in the case of air heater failure for a short duration

Fiberglass Reinforced PTFE Expansion Joints (Series 500T)

- Designed for use for wet or dry services up to 575°F and 5 psig

- Constructed from fiberglass reinforced PTFE with a zero porosity gas barrier of varying thickness ranging from 5mils to 30mils and mechanically bonded to the substrate

- Consists of the highest resin content in the industry

- Primarily used to provide the outer cover and gas seal for high temperature composites but also can be used in extreme chemical service as the primary flex element or inner gas seal

- Typical applications range from paper processing liquors to wet scrubbers

- Require a flow liner in most cases if used a single layer solution

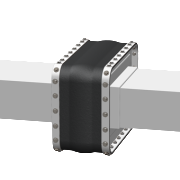

Multi-Layered Expansion Joints (Series 500HT – 1000HT)

- Designed for high temperature air and gas applications up to 1000°F

- Constructed from multiple layers based on design temperature requirements utilizing components including gas barrier, insulation, woven fabric, and possibly knitted or woven wire mesh

- Typically manufactured for economizer outlets, SCR inlets, secondary air, and other hot flue gas applications

- Requires a flowliner and should not be externally insulated

- Outer cover can be constructed using several different materials including EPDM, Viton, PTFE, or metal alloys based on design conditions

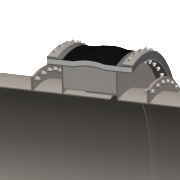

HTG Extreme Temperature Expansion Joints (Series 1200)

- Specifically designed for gas turbine applications where temperatures are above 1000°F and heavy cycling, radial growth, and large movement is expected

- HTG joints are designed to provide long life, easy installation, low external temperature and reduce noise

- HTG joints are found on GT exhausts, HRSG inlets and other high temperature applications

- Designed for ducting and fan applications