Applications

Types of Expansion Joints

Expansion joints are designed safely to absorb movement, noise, and vibration within a piping or ducting application. Below, we have compiled types of expansion joints offered at Holz Rubber. Depending on your application, our expansion joints are manufactured to meet certain criteria, such as media moving through the joint, pressure and temperature within the system, and life expectancy. A Holz representative will work with you to determine the best solution.

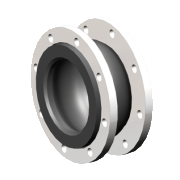

Single Arch Type

- Spool “Arch” Type is a full face integral flange design available in both single and multiple arch types

- Construction is of fabric and rubber, reinforced with metal rings or wires

- Flanges are integral with the body and drilled to conform with the bolt pattern of the metal companion flange

- Face flange is sufficient to form a tight seal without the use of gasket

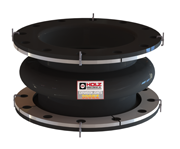

Multiple Arch Type

- Spool “Arch” Type is a full face integral flange design available in both single and multiple arch types

- Joints made of two or more arches

- May be manufactured to accommodate movements greater than those of which a single joint is capable

- Length of the joint is dependent on the number of arches

Lightweight Type

- Lightweight type comes in single or multiple arches

- Designed for lower pressure and vacuum applications

Reduced or Taper Type

- Connects piping of unequal diameters

- Available concentric or eccentric

Offset Type

- Custom built expansion joint

- Compensates for initial misalignment

TFE/FEP

- Teflon® liners are made to resist most chemicals

Sleeve Spool Type

- Slips over the pipe and secured with a clamp

- Available in single or multiple arch

Enlarged End Type

- Manufactured as a spool or lightweight type

- Sleeve ends are manufactured to the O.D. of the pipe

- Available with a filled arch

Filled Arch Type

- Inside of arch is filled with rubber

- Filled arch decreases joint flexibility by 50%

- Used to protect from abrasive slurry

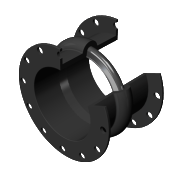

Floating Flange Spherical Molded Type

- Designed with a long radius arch to provide additional movement

- Carcass doesn’t contain metal reinforcements

- High burst pressure

- Generally available for pipes sizes under 30”

- Single or double arch design

Integral Flange Spherical Type

- Designed with a long radius arch to provide additional movement

- Full face flanges are integral part of the body

- Designed with a weave fabric for pressure resisting strength

Teflon Lined Type

- Designed with a long radius arch to provide additional movement

- Resistant to mechanical damage, permeation and the non-stick smooth surface finish provides excellent release properties.

- Full face flanges are integral part of the body

- Designed with a weave fabric for pressure resisting strength

Wide Arch Type

- Available in a metallic and non-metallic reinforced design

- Wide arch type features greater movements than the standard spool arch type

- The non-metallic wide arch type carcass does not contain wire or a metal ring

- Available with a filled arch design

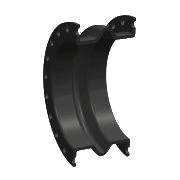

“Top Hat” Liner

- Sleeve through the bore or joint

- Reduce friction wear

- Constructed of hard rubber or metal